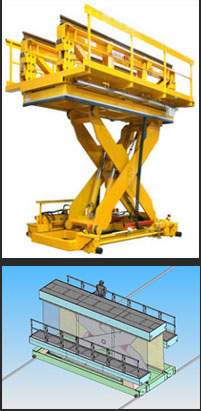

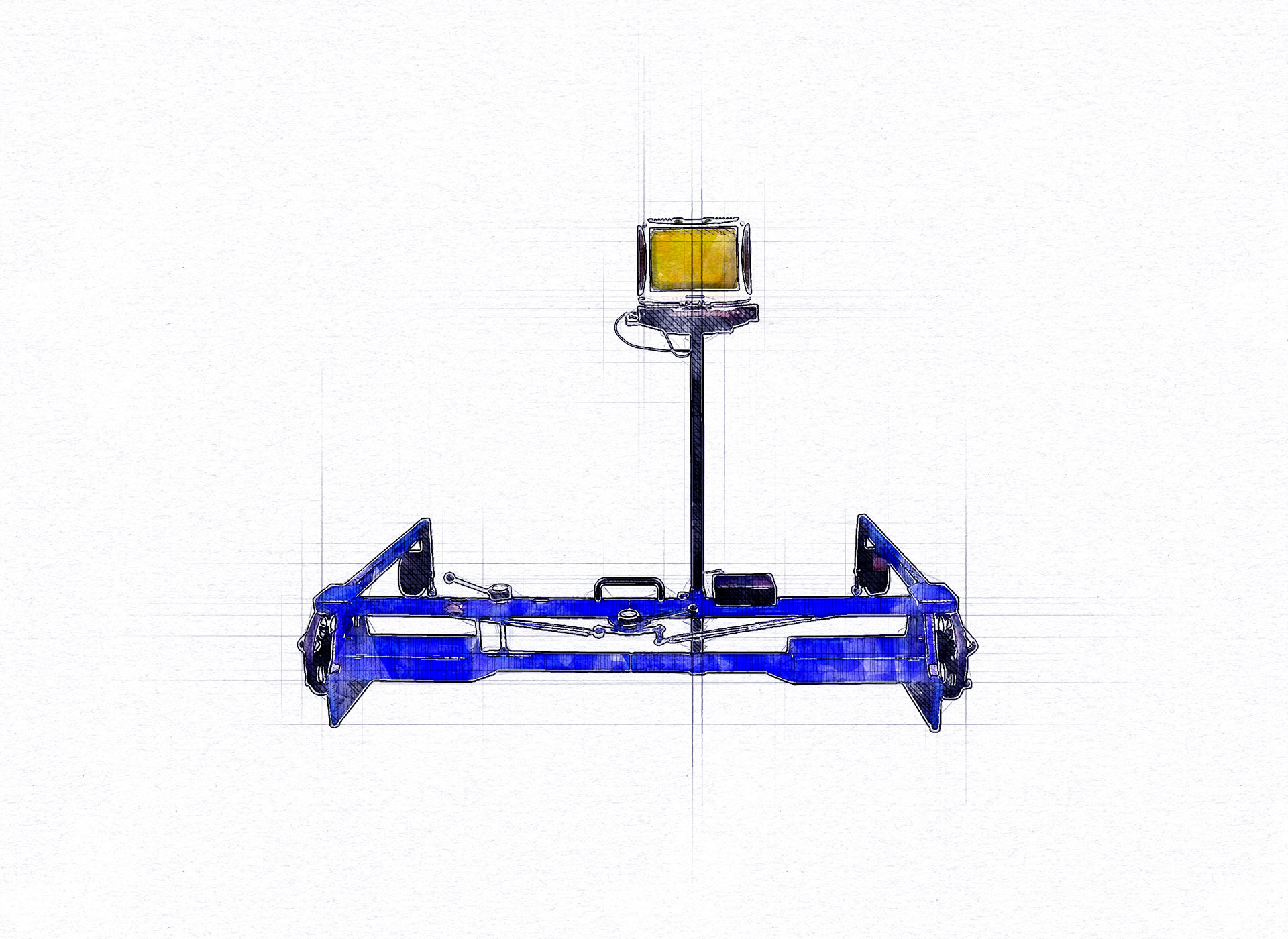

Truck Drop Table

SE002

Key Specifications

- Expert servicemen onsite to install or/and maintain the equipment

- The capacity of 120 tons

- Cost-effective

OVERVIEW

Expert servicemen onsite to install or/and maintain the equipment.

Capacity of 120 tons.

Cost effective.

Contact us for more information

TECHNICAL DATA OF DROP TABLE

Max. Lifting capacity: 120 tons

Max. Lifting capacity (truck): 30 tons

Override (T.O.R.): 1.97”

Lifting speed: max. 1.6”/sec.

Max. Traversing speed: max. 19.7 ft./min

Operating voltage: t.b.a.

Control voltage: t.b.a.

Protection: IP 55

Power supply: via energy chain

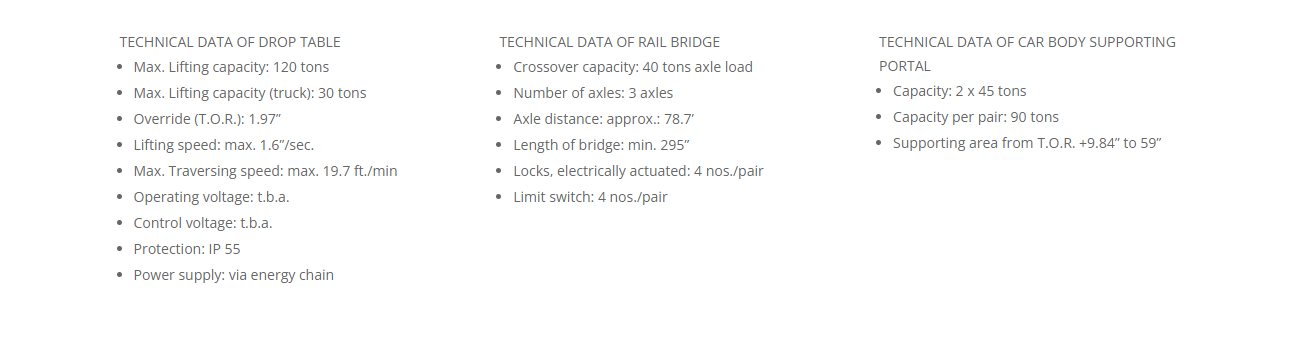

TECHNICAL DATA OF RAIL BRIDGE

Crossover capacity: 40 tons axle load

Number of axles: 3 axles

Axle distance: approx.: 78.7’

Length of bridge: min. 295”

Locks, electrically actuated: 4 nos./pair

Limit switch: 4 nos./pair

TECHNICAL DATA OF CAR BODY SUPPORTING PORTAL

Capacity: 2 x 45 tons

Capacity per pair: 90 tons

Supporting area from T.O.R. +9.84” to 59”