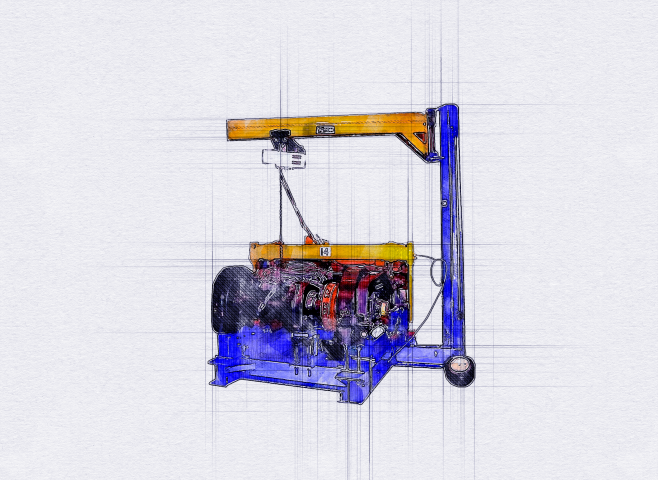

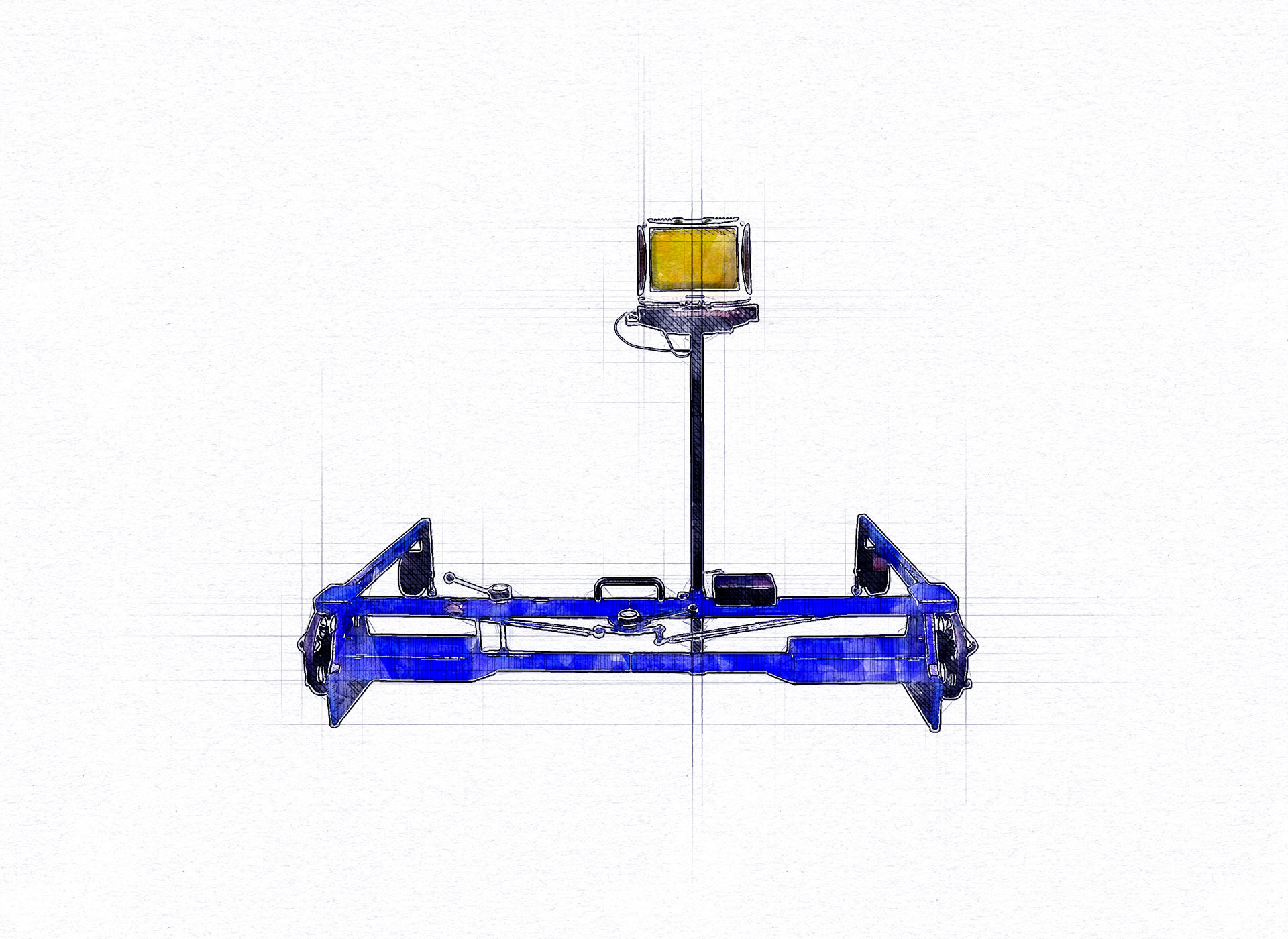

Motorized / Manual Turntable

SE001

Key Specifications

- The simplicity of design and ease of manual operation

- Customized to your needs

- Frequent servicing from trained professionals

OVERVIEW

Simplicity of design and ease of manual operation.

Customized to your needs.

Frequent servicing from trained professionals.

Contact us for more information

Contact us for more information